I grew up passionate about having massive tattoo stickers on my hands. We just stick the sticker somewhere in the middle of our hands and press hard for a few seconds.

We take the plastic paper out (the stuff that covers the printed part from the outside), and boom, we’ve just got a fun tattoo so we can share it with our friends in elementary school.

At that time, around the early 19th century, it was pretty much fun and cool. Growing up, I was still attached to stickers, but this time it was with jeans.

In the 2010s, a friend and I started a small business printing pictures on jeans. Although it was not a unicorn among startups at the time, it ran smoothly.

Then we applied some new technology. Instead of printing the image directly on the jeans with laser printers (direct thermal printing), we used transfer papers or heat transfer papers that can give very similar results and some good things for the jeans’ preservation.

I know it can be pretty competitive since there are tons of DIY transfer papers on the market that encourage people to do this thing at home with an iron.

But there’s way too much technological heat transfer paper, which gives pretty much varying results on jeans.

And with my experience, I know what is best for your jeans and expectations.

However, at this moment, I am just a free writer, and that’s why this article is not biased at all.

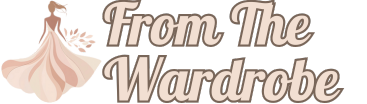

So let’s just dive into the question “Can you use transfer paper on jeans?” and I am going to give you everything you need to know about this field.

Quick Navigation

Can you use transfer paper on jeans?

This is a great printing technology and jeans are tough enough so there’s no reason why you can’t use transfer paper on jeans. But for those who are new in this field, you need to know what a transfer paper is.

What types of transfer paper for jeans?

This type of paper is part of a dynamic printing technology called thermal transfer printing. Papers are impregnated with certain chemicals that change color when subjected to heat. This is because these chemicals react with the LEUCO Flouran in the dye and will adhere to the surface of the material when exposed to high temperatures.

In general, this technology of printing on jeans has many outstanding advantages compared to direct thermal printing.

This process of printing on jeans requires the use of printers to print images, text, or any design on thermal transfer paper. Then, you need to put the printed transfer paper on the surface of the jeans and conduct heat to make the image stick to the surface of the material perfectly.

There are many pre-printed heat transfer papers with designs on the market. Just buy them and use your home iron to give your jeans a new look. But the biggest drawback is that you can’t choose the image you want for yourself. There are only a few designs of transfer paper available in the store.

But you’ve got another way to customize your idea for your jeans. That is to go with some small printing startups like mine before. You may need to do a little research on heat transfer papers to see which one is best for you.

Inkjet Transfer Paper

This is the most popular and, by far, the least expensive type of paper. It is relatively suitable for casual printing on jeans at home or in a small business. This paper is used by inkjet printers and laser printers to create heat transfer paper before being applied to jeans.

Basically, the ink from the printer will be saved on the inkjet transfer paper, and when the heat process is done, either by heat press machine or iron, the printed jeans can be pretty soft, washable, and stretchable as your jeans stretch.

Regardless of dark or light jeans, this printing method can be effectively applied. If you are about to transfer some text to your jeans, you should be aware of reverse printing when applying this paper. Besides, you may not have as many color choices and image sharpness when using ink transfer paper.

Applied fabrics: highly recommended 100% cotton and cotton blend with great cotton content

Sublimation Transfer Paper

These papers are relatively dynamic, they have the ability to convert ink into a gas without undergoing liquefaction.

Therefore, the ink will not smudge during the heat press stage. When the ink is in a gaseous state, it adheres to the fabric and stays there forever.

The advantage of this paper is that you can be assured of the sharpness and variety of colors of the designs on jeans, but it may not be a good idea for dark-colored jeans.

However, due to the high cost, I do not recommend applying in small quantities.

Applied fabrics: Cotton jeans with great amount of synthetic textiles

Hot-peel Transfer Paper

This is the type of paper that requires peeling off the backing layer immediately after pressing heat during the ink transfer process into jeans.

Due to this heating, complete ink saturation is unlikely. Therefore, the surface of the jeans fabric will remain soft along with the sharp image. This is beneficial to prolonging the life of the denim fabric.

However, like inkjet paper, you may not have many color choices for your graphic designs. However, they are much cheaper than sublimation transfer paper.

Applied fabrics: any cotton jeans, polyester and cotton blends.

Cold-peel Transfer Paper

The process is very similar to hot-peel transfer paper. Cold-peel transfer paper does not require the backing to be removed immediately after pressing heat but waits for it to cool completely.

This allows more color to be transferred into the jeans, so the final design comes out brighter and sharper than with hot-peel transfer paper.

Applied fabrics: any cotton jeans, polyester and cotton blends.

What types of jeans can be used to transfer paper?

Jeans are sturdy enough for applying heat and transfer paper. Yet, different types of jeans come with different results of printing depending on which type of paper that you use.

100% Cotton jeans

In fact, these jeans are made from 100% cotton and have a durable and strong construction. They even use double weaving to increase the thickness and strength of the material. As a result, you rarely see smooth-surfaced 100% cotton jeans like silk or polyester fabrics.

This allows the jeans to withstand heat up to 380 degrees Fahrenheit for about 10-15 minutes during the thermal transfer printing process.

No surprise, the quality, and construction of the fabric are also not greatly affected, and the pants can still last many years later.

However, the standard gradation and the vividness of the pictures and texts on the fabrics vary between different heat transfer papers, as mentioned above.

Keep in mind that 100% cotton jeans may not be too suitable for applying sublimation transfer paper due to the fact that the gasification of the ink on this paper may not guarantee perfect durability and permeability in the fabric for a long time.

Therefore, for 100% cotton jeans that have a thick and stiff fabric structure, inkjet transfer paper with liquid inkjet ink are the better choice.

Stretchy jeans

Stretchy jeans typically have a small amount (a few percent of the fabric) of elastane or spandex mixed in with the rest of the cotton to increase wear elasticity, enhancing the wearer’s overall comfort and satisfaction.

The texture of stretchy jeans is softer and thinner than that of 100% cotton, so they can be ideal for applying all of the above transfer papers in the heat transfer printing process.

However, you will probably need to be aware of the temperature of the heat press machine or iron when doing this process. You will probably need to lower the temperature than 100% cotton jeans and prolong the heat transfer to get a good effect without shrinking the fabric too much.

Polyester jeans

Polyester jeans are the most popular line of jeans because of their low price and acceptable quality.

They contain cotton (roughly 20–25%), elastane/spandex (about 5%), and the rest, polyester. These jeans somewhat have poor breathability but look pretty stylish and elegant because the fabric surface is relatively smooth compared to 100% cotton jeans.

This allows your prints on polyester jeans to appear better, more complete and vivid. You can use hot-peel or cool-peel transfer papers on polyester jeans effectively.

Sublimation transfer paper on polyester jeans (which is recommended and contains > 85% of poly in their construction) also has good adhesion and coloring ability.

Polyester jeans are the most commonly used material to produce multi-colored jeans such as yellow, tan, red, or teal.

What should be cautious when applying transfer papers on jeans?

Doing this process at home can be pretty risky somehow. Here are what you need to consider carefully.

High temperature

Since all jeans are about to shrink when exposed to high heat, this should be the first thing you need to be concerned about.

In the very early days of running my startup with no previous experience, I once made the left side of a customer’s 100% jeans pants shrink by 2 inches when I did a full heat transfer printing of the image on that leg at a high temperature of 400 degrees F.

It was a very unfortunate accident, and I did apologize and properly compensate my customer later.

The lesson here is that if you’re printing a very large area of the image onto jeans (like all over the legs or the buttocks), you’ll need to pay close attention to the temperatures used during the printing process.

Keep in mind that 100% cotton jeans tend to shrink better due to their plant-based fabrics.

For up to 15 minutes, 100% cotton jeans can withstand temperatures of around 380 degrees F.

For polyester jeans, only set the temperature at 270-300 degrees F for 10 minutes.

Stretchy jeans can be fine with a temperature of about 330 degrees F, and it is better to extend the printing time by about 12–24 minutes.

Number of colors of the picture

If your design is monochrome or only contains 2-3 primary colors, they can be handled at ease when applying heat transfer printing at home with transfer papers and your iron.

But if you expect to have a perfect print on jeans with massive colors and tiny patterns, you’d better go see some professional with a quality machine to do that for you.

Inkjet printers are the most commonly used, but the most advanced models can only apply 12 colors at most. Normal inkjet printers have 3 colors in total. This limits the color choices of your ideas.

Washing jeans right away

Many people can’t stand the unpleasant chemical smell that lingers on their jeans after being heat transfer printed. They immediately took those pants to the washer with soap. This will definitely smudge or fade the color of the printed images in one way or another.

I usually advise my clients to wait 3-5 days before they decide to wash their jeans after the heat transfer print is done. This time may be shorter for cool-peel transfer paper, while it may be slightly longer when inkjet transfer paper is applied.

Besides, if your prints have bold and heavy pigments, you should never wash them with soap afterwards.

Instead, you can mix water and apple cider vinegar with a ratio of 3 to 1 to remove bacteria from the fabric when it smells sour and fishy.

Before you leave..

Well, it is definitely a very laborious, risky, and time-consuming process. Normally, the perfect heat transfer printing requires pretty high quality machines to get things done.

Personally, I don’t recommend applying heat transfer paper on thick jeans, such as 100% cotton jeans, at home since they tend to shorten the quality of the printed image and its lifespan. But if that’s your choice, you’ll need a printer, transfer paper, and an iron.

If the professionals do it for you, they will have different transfer papers suitable for your jeans construction and the pictures.

It is fair enough that they also have pretty different types of specialized heat press machines with adjustable temperature and time. It’s all about ensuring that your final product is flawless.

Hi, I’m Grace Alision, a fashion lover with a passion for helping women feel confident and beautiful through their style choices. I created this website to share my love for wedding guest dresses and, in the future, to explore concert outfit inspiration. Dresses have always been my favorite way to express elegance and individuality, and I’m here to make finding the perfect outfit fun and easy. When I’m not working on outfit ideas, I love discovering new trends and connecting with others who share my love for fashion.